acf domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /home/tanoujo/domains/web01.tanoujo.com/repo/wp-includes/functions.php on line 6121

Professional dosing equipment is required for problem-free processing and application of adhesives. Ease of use and speed is, of course, of great importance, while maintenance intervals must be kept to a minimum while operating reliability must be optimal.

Tanoujo has developed an automated adhesive system for the sandwich panel industry. With this system, you can apply glue to your vacuum tables in a fully automatic manner.

The adhesives can be processed directly from IBC containers. The adhesives are automatically pumped from the IBC containers to the buffer tanks of the Tanoujo PPM machine. The transport hoses are connected to the machine via a cable guide against the wall, clear of the floor. The central cable routing also supplies power and air to the PPM machine. The buffer tanks in the PPM machine are equipped with level sensors. When the adhesive level in the buffer tank falls below the middle level, the tank is automatically filled until the high level is reached. A sensor on the bottom level prevents the pumps from being fed additional adhesive. When the bottom level is reached, the machine is then switched off. The buffer tanks make it possible to change the IBC tanks while using the machine without production downtime.

The PPM machine is equipped with high-precision gear pumps. AC motors drive the gear pumps with an automatic feedback function. The correct output of the gear pumps is checked through the DV system developed by Tanoujo. Thanks to the high volumetric efficiency of the pumps used, the actual flow rate (the adhesive output) of the pumps during the production process are accurately determined utilizing a controlled electronic speed. During pressure mode, when the dosing head is closed, the internal leakage in the pump is measured. If the actual flow deviates from the theoretically expected flow, this deviation is signalled. The flow can also be controlled manually via a unique pump test program. All data is stored in a data logger.

The powerful Tanoujo PLC determines the mixing ratios and the yield per square meter. The PPM machine is equipped with the FlexHead mixing gun to apply the adhesive via the three different adhesives fed separately to the mixing gun. Depending on the ratio between the two A-components and the glue ratio with the B-component, the three types of glue are mixed in the integrated static mixer. The mixing balance between the two A components can be automatically adjusted during production. The outside temperature, the humidity and the desired ‘pot life’ or ‘open time’ of the adhesive, which can be set, are taken into account. The system then determines the mixing ratios fully automatically based on ambient temperature and humidity.

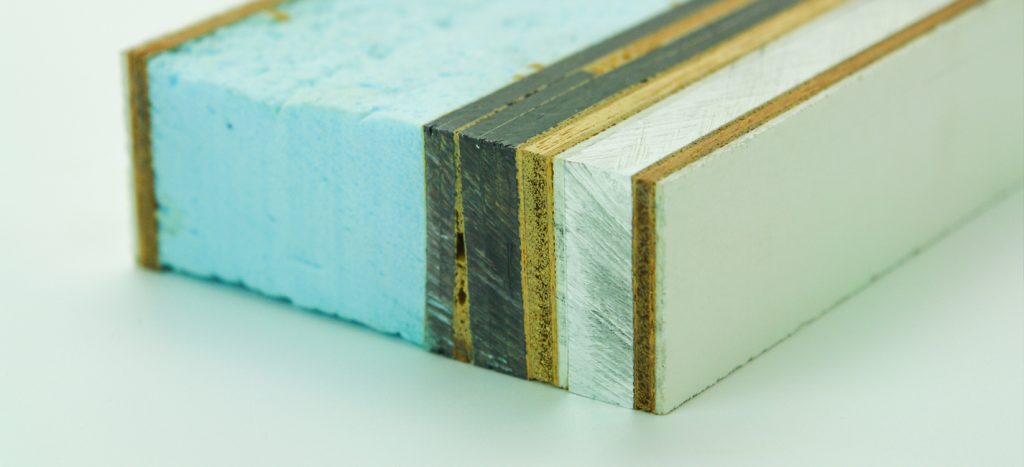

Various mixing tubes are available to mix the most difficult adhesives. The spreader, which distributes the adhesive, is connected directly to the mixing tube. This spreader distributes the glue in nice glue strips over the panel with a center to center distance of 5 mm. With a yield of 250 grams / m2, this in most cases results in a full-surface glue pattern after pressing. Both the mixing tube and the spreader are disposable and can be disposed of with normal waste after production.

All settings necessary for correct adhesive delivery can be entered on the touchscreen. The specific gravity of the adhesives, mix ratios, pump size, regeneration times, settings for the DV system, and other essential settings.

The bonding of structural building elements in precast factories is increasingly becoming the industry standard. Prefab assembly processes are increasingly replacing conventional and often more complex joining techniques. In this way, various materials such as plastic, glass, wood and metal can be connected durably and reliably. This also creates new possibilities in terms of functionality and design. The applications of the mixing and dosing systems from Tanoujo vary from the bonding of facades, frames and roof parts.

Tanoujo offers innovative and influential dosing and mixing systems adapted to the processing and application requirements of “heavy” adhesives with many fillers. The extensive portfolio ranges from manual applications to automated bonding and joining processes. Absolute process stability must be guaranteed for optimum product quality. This means an optimal mixing ratio and precise dosage in terms of shape, volume and position. No excess mixed liquid and less waste because mixing is done at precisely the right time in the right volume.

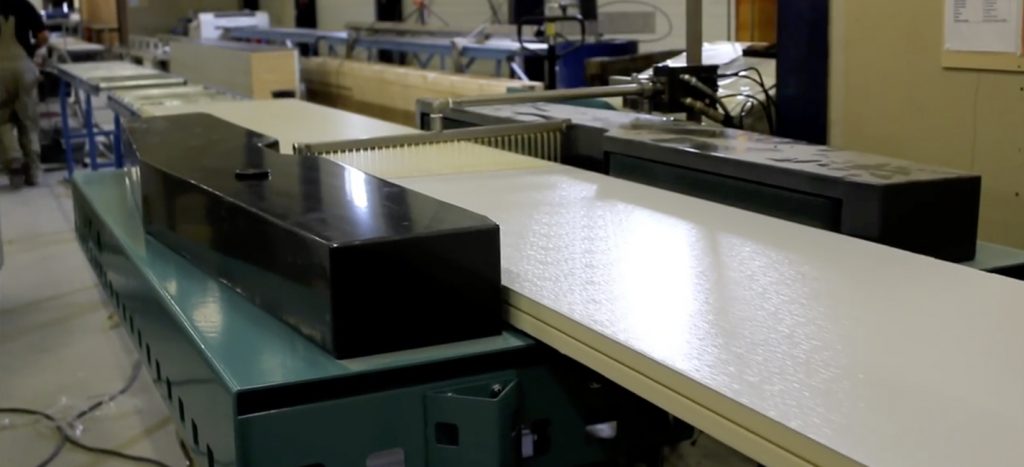

FlexBot-machines are designed to automatically distribute two- or three-component polyurethane adhesives for the industrial production of large sandwich panels such as refrigerators and van panels and wall panels for modular homes.

The machine works automatically via the crane track that can be up to 100 meters long, above several vacuum tables. The process is easy to operate via the HMI panel. Simply select the panel size on the HMI, place the spreader in the corner of the laminated panel, set the application direction and press the start button, and the machine will do the rest.

The FlexBot-machine spreads a pre-measured adhesive layer over your sandwich panels. The adhesive is applied longitudinally, which means that the machine uses the adhesive in stripes at high speed and only starts and stops a little. The system can be specified with a 1K, a 2K and a 3K adhesive. The 3K adhesive system uses a combination of a fast and slow A-component. This is to be able to achieve a continuously variable curing speed. Using a 3K or 3-component adhesive system further shortens production cycles by up to 50%. This is done by adjusting the cure speed for each layer of the panel to all cure simultaneously. Because of the highly automated system, adhesive consumption will decrease by 25 %.

The FlexBot-machine is easy to use and operate thanks to our easy to replace plastic mixing tubes and 350 mm wide spreaders. Rinsing with solvent is not necessary. Only simple maintenance is required when using this glueing machine.